Comprehensive Analysis Of Elevators: Types, Principles, And Application Selection Guide

Elevators are core equipment used for vertical or large-inclination material conveying in modern industry, widely applied in fields such as mining, building materials, grain, chemical industry, ports, and construction. They drive hoppers or carrying devices through traction components (such as belts and chains) to realize continuous or intermittent conveying of materials from low to high positions. The following is a systematic introduction from the aspects of types, working principles, selection points, and safety maintenance:

I. Main Types and Characteristics

1. Bucket Elevator

- Applicable Materials: Powder, granular, and small materials (such as cement, grains, coal).

- Traction Methods: Divided into belt type (stable operation, suitable for normal temperature materials) and chain type (high temperature resistant, wear-resistant, suitable for large块状 materials).

- Discharging Methods: Centrifugal type (high-speed throwing, suitable for dry fine materials), gravity type (low-speed self-flowing, suitable for large块状 or viscous materials).

- Advantages: Large conveying capacity, high lifting height (up to 40 meters), compact structure and good sealing performance.

2. Plate Chain Elevator

- Application Scenarios: Large, high-temperature, or highly abrasive materials (such as ores, coke).

- Characteristics: Using plate chains as traction parts, with strong bearing capacity and high temperature resistance, but slow running speed and high energy consumption.

3. Vertical Screw Elevator

- Application Scenarios: Short-distance, small-flow powder or small granular materials.

- Characteristics: Pushing materials through the rotation of screw blades, with simple structure but limited lifting height.

4. Mine Elevator

- Specialized Field: Lifting ores, coal, personnel, and equipment in mine shafts or inclined shafts.

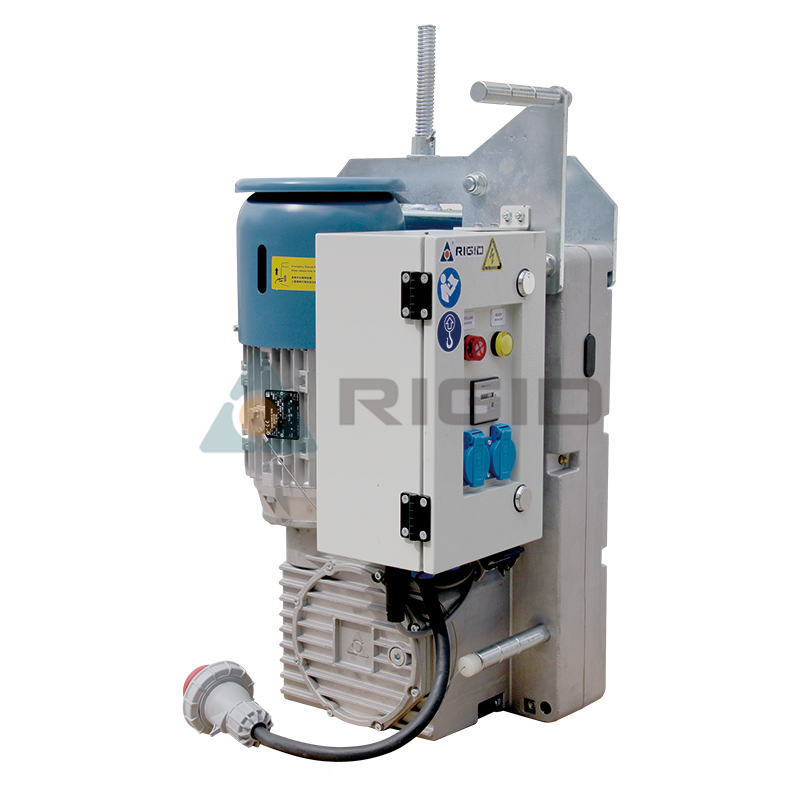

- Safety Requirements: Equipped with high-strength steel wire ropes, multiple braking systems, and intelligent control to ensure heavy-load safety.

5. Hydraulic Elevator

- Application Scenarios: Linear lifting scenarios (such as car lifts, injection mold lifting).

- Characteristics: Large thrust, stable operation, precise positioning, but lifting height is limited by hydraulic cylinders.

II. Working Principle

The core process of the elevator is divided into four steps:

1. Loading: Materials flow into the hopper or carrying device from the bottom feed inlet.

2. Lifting: The traction component drives the full hopper to rise vertically.

3. Discharging: When reaching the top, the materials are thrown into the discharge outlet by centrifugal force or gravity.

4. Returning: The empty hopper descends to the bottom for cyclic operation.

III. Key Selection Factors

1. Material Characteristics: Particle size, humidity, abrasiveness, and temperature (for example, high-temperature materials need to be selected with chain type or heat-resistant design).

2. Conveying Requirements: Lifting height, conveying capacity (t/h), and operating environment (explosion-proof, anti-corrosion requirements).

3. Energy Consumption and Maintenance: Chain type is durable but has higher energy consumption; belt type has lower cost but needs regular replacement.

4. Safety Standards: Need to comply with equipment protection, braking performance, and load specifications, such as mine elevators need to meet mining safety standards.

IV. Safety and Maintenance Recommendations

1. Operational Specifications: Start with no load, feed uniformly, strictly prohibit overloading, and prohibit contact with moving parts during operation.

2. Daily Inspection: Regularly check the tension of traction parts, the wear condition of hoppers, and the lubrication status of bearings.

3. Fault Prevention: Clean up the accumulated materials at the bottom to avoid blockage, and timely replace damaged hoppers or chains.

The correct selection and maintenance of

elevators are directly related to production efficiency and safety. It is recommended to select the appropriate type according to actual material characteristics, conveying capacity, and environmental requirements, and strictly follow safe operating procedures.