Comprehensive Analysis Of Electric Hoists: Types, Principles, And Safety Buying Guide

An electric hoist is a mechanical device that uses electric power to drive vertical or inclined lifting, lowering, and transportation of heavy objects through core components such as an electric motor, reduction mechanism, drum, or chain. As an indispensable lifting equipment in modern industrial, construction, warehousing, and logistics fields, its efficiency and reliability are highly favored. The following provides a detailed introduction from the aspects of types, principles, safe operation, and purchasing points.

I. Main Types and Characteristics

1. Wire Rope Electric Hoist

It uses wire rope as the load-bearing component, featuring a large lifting height, fast running speed, and strong load capacity. It is suitable for high-intensity operation scenarios such as construction sites, mines, and ports.

2. Chain Electric Hoist

It adopts a high-strength lifting chain, with a compact structure, light weight, and high safety (mostly equipped with a dual braking system). It is suitable for frequent operation environments with limited space such as factories and warehouses.

3. Mini Electric Hoist

With a lightweight design and small lifting capacity (usually 0.25-2 tons), it supports 220V household power supply and is suitable for light lifting needs in home garages, repair shops, etc.

4. Winch

It has high power and flexible installation, mainly used in tension operation scenarios such as civil engineering and ship towing.

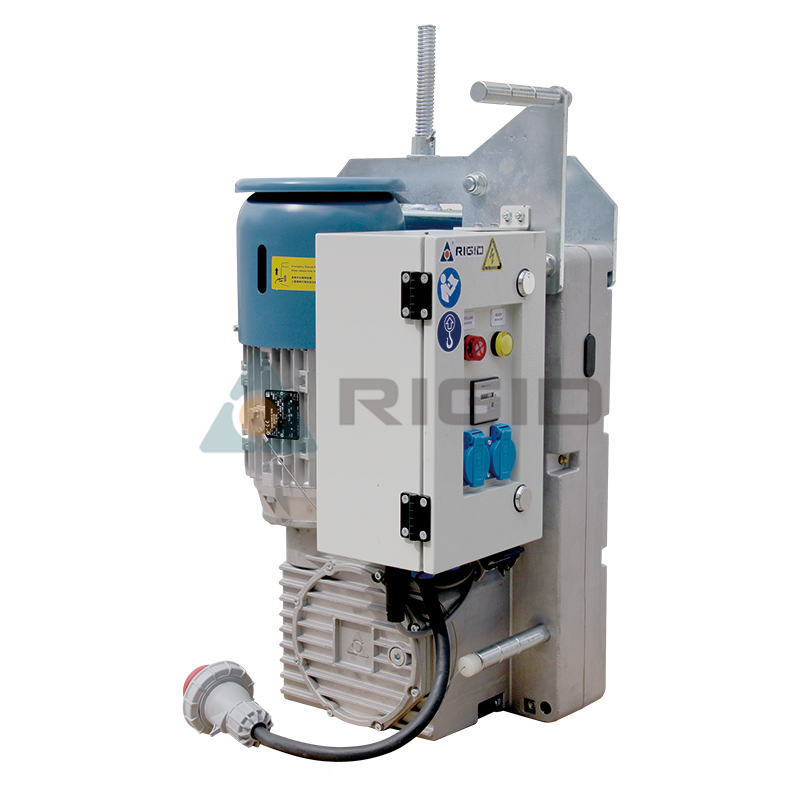

II. Core Working Principle

The electric hoist is powered by an electric motor, which reduces the speed and increases the torque through the reduction mechanism, driving the drum or sprocket to wind the wire rope/chain to realize the lifting and lowering of heavy objects. Key components include:

- Braking system: Ensures reliable braking of heavy objects when power is cut off or stopped;

- Control system: Achieves precise operation through button switches, limiters (anti-over-hoisting), etc.;

- Hook/sling: Directly connects to the load, and its firmness must be ensured.

III. Safe Operating Procedures

1. Pre-use inspection: Daily inspection of the hook, wire rope/chain, and brake for good condition;

2. No overloading: Do not exceed the rated lifting capacity to avoid equipment damage or accidents;

3. Load balance: Ensure the center of gravity is stable and the binding is firm to prevent sliding or falling;

4. Personnel safety: No standing under heavy objects, and operators should stay away from dangerous areas;

5. Vertical operation: Avoid oblique pulling to reduce the impact of lateral force on the equipment;

6. Smooth operation: Start and stop slowly to prevent load swinging;

7. Abnormal handling: Immediately stop and report for repair if faults such as abnormal noise or odor are found.

IV. Purchasing Guide

1. Rated lifting capacity: Choose a model slightly higher than the actual maximum demand (reserved safety margin);

2. Lifting height: Determine the length of the wire rope/chain according to operational needs;

3. Working voltage: 380V three-phase electricity is commonly used in industry, and 220V single-phase electricity is optional for light equipment;

4. Usage environment: Outdoor use requires waterproof and rust-proof performance, and explosion-proof scenarios require special models;

5. Installation method: Fixed type or equipped with a running trolley (movable on I-beam);

6. Quality certification: Priority is given to brand products with safety certifications and qualifications.

V. Development Trends

With the advancement of technology, intelligent hoists have gradually applied electromagnetic levitation, AI algorithms, and Internet of Things technology to achieve precise control, energy consumption optimization, and predictive maintenance. In the future, they will further expand in the fields of high efficiency, energy saving, and automation.

Summary:

Electric hoists are key equipment to improve operation efficiency, but safety is always the primary principle. Correct model selection, standardized operation, and regular maintenance are the basis for ensuring their long-term stable operation.