The construction industry is governed by stringent requirements for operational safety, productivity optimization, and reliability—parameters that directly influence project timelines, cost efficiency, and regulatory compliance. Traction hoists, as specialized lifting equipment, have emerged as indispensable assets in modern construction, offering technical advantages over traditional drum-based hoists through their friction-driven mechanism. From material handling to personnel access in high-rise projects, these devices deliver targeted solutions to the industry’s most pressing challenges. This article systematically elaborates on the core benefits, technical characteristics, application scenarios, and selection criteria of traction hoists in construction, providing engineering insights for equipment integration and project optimization.

1. Technical Fundamentals of Traction Hoists

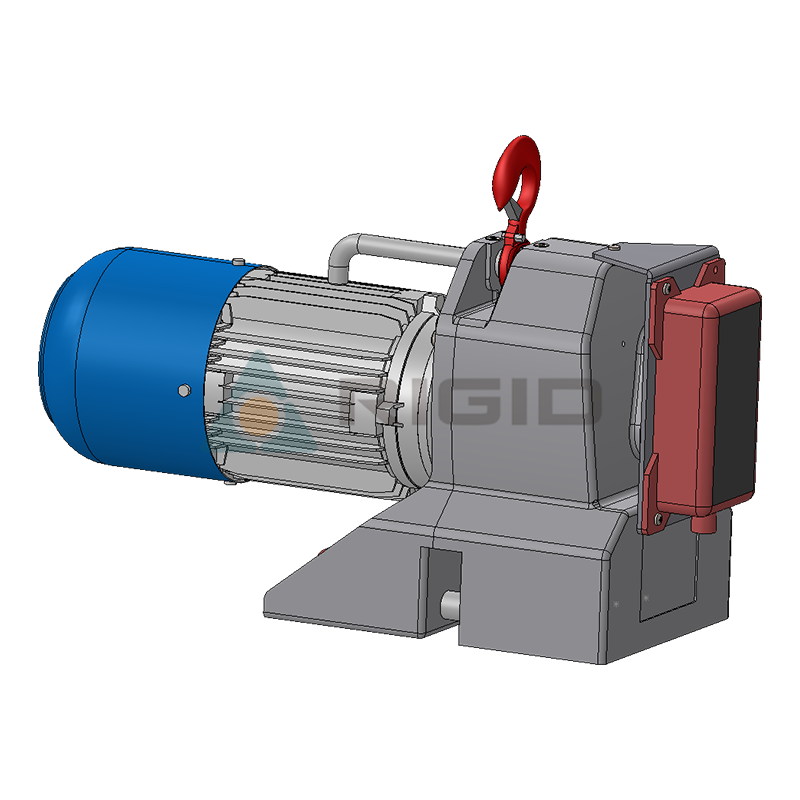

A traction hoist (also referred to as a friction hoist) is a lifting device that utilizes a traction drive mechanism—typically consisting of a grooved sheave, high-tensile steel wire rope/cable, and friction pads—to transmit lifting force. Unlike conventional drum hoists, which wind rope around a rotating drum, traction hoists rely on frictional force between the sheave and rope to achieve smooth, continuous lifting/lowering motion. Key technical attributes include:

- Traction Drive System: Delivers stepless speed regulation (0.5–10 m/min) and uniform load distribution, minimizing mechanical shock during operation.

- Self-Locking Mechanism: Compliant with EN 13157 and ANSI/ASME B30.16 standards, featuring a fail-safe brake system that prevents load free-fall even in power outages or mechanical failure.

- Load Capacity Range: From 0.5 t (manual models) to 50 t+ (electric heavy-duty variants), with precision load control (±5% of rated capacity).

- Structural Design: Compact footprint (typically 30–50% smaller than drum hoists) and modular construction for enhanced portability and on-site adaptability.

1.1 Core Product Classifications

| Type | Technical Specifications | Target Applications |

|--------------------------|------------------------------------------------------------------------------------------------|---------------------------------------------------|

| Electric Traction Hoists | 3-phase AC power (380V/415V), variable frequency drive (VFD) for speed control, load capacity 1–50 t. | High-rise construction, heavy material lifting, continuous operation. |

| Manual Traction Hoists | Hand-cranked operation, gear ratio 40:1–60:1, load capacity 0.5–5 t, no power dependency. | Small-scale projects, remote sites, emergency backup. |

| Tirak Traction Hoists | Compact design, integrated overload protection, load capacity 1–10 t, compatible with suspended scaffolding. | High-frequency lifting/lowering, facade maintenance, temporary access systems. |

| Portable Traction Hoists | Lightweight aluminum alloy frame (<20 kg), quick-connect fittings, load capacity 0.5–3 t. | Mobile construction sites, interior fit-outs, short-distance lifting. |

2. Key Benefits in Construction Applications

2.1 Enhanced Safety & Regulatory Compliance

Safety is paramount in construction, and

traction hoists are engineered to mitigate operational risks:

- Fail-Safe Self-Locking Mechanism: The mechanical self-locking brake engages instantaneously under load loss or power failure, complying with OSHA 1926.550 and EN 14960 standards for personnel lifting. Load-bearing components undergo non-destructive testing (NDT) per ASTM E165 to ensure structural integrity.

- Overload Protection: Integrated load cells or mechanical overload clutches prevent operation beyond rated capacity (typically 110–125% of nominal load), reducing the risk of equipment failure and structural damage.

- Stable Suspended Operation: For scaffolding applications, traction hoists maintain constant tension (±2% of rated load), preventing sway and ensuring worker safety at heights exceeding 100 m.

2.2 Improved Operational Efficiency & Productivity

Traction hoists optimize construction workflows through technical performance advantages:

- Continuous Smooth Operation: The traction drive eliminates rope winding/unwinding delays, enabling uninterrupted lifting cycles. Electric models achieve lifting speeds of 3–10 m/min, reducing material hoisting time by 30–40% compared to drum hoists.

- High Load-to-Size Ratio: Compact design allows installation in confined spaces (e.g., elevator shafts, narrow building cores) while maintaining high load capacity, maximizing usable workspace on dense construction sites.

- Low Maintenance Requirements: Sealed gearboxes and corrosion-resistant components (stainless steel wire ropes, galvanized frames) extend maintenance intervals to 500 operating hours, minimizing downtime.

2.3 Versatility Across Construction Tasks

Traction hoists adapt to diverse construction requirements, eliminating the need for multiple specialized devices:

- Material Handling: Capable of lifting construction materials (steel beams, concrete panels, bricks) and equipment (power tools, generators) with precision, supporting load weights from 500 kg to 50 t.

- Suspended Scaffolding: Tirak and portable variants provide stable support for suspended platforms, accommodating 2–10 workers and their tools, with adjustable lifting speeds for facade installation/maintenance.

- Personnel Access: Certified personnel hoists (EN 14960 Class A) enable safe transport of workers to elevated work areas, with features such as emergency stop buttons, interlocked access gates, and anti-capsize protection.

- Temporary Structural Support: Used for tensioning cables, supporting formwork, and aligning precast components, ensuring structural accuracy during assembly.

2.4 Portability & On-Site Adaptability

Construction sites often require equipment mobility, and traction hoists are designed for ease of deployment:

- Lightweight & Compact: Manual and portable models weigh <20 kg, facilitating transport via elevators, scaffolding, or manual carrying across large sites.

- Quick Installation: Modular design with quick-connect mounting brackets and pre-wired electrical systems (for electric models) reduces setup time to 15–30 minutes per unit.

- Power Flexibility: Electric models operate on standard construction site power (380V 3-phase), while manual variants eliminate reliance on electricity—ideal for remote locations or power-constrained sites.

2.5 Long-Term Cost-Effectiveness

Traction hoists deliver significant total cost of ownership (TCO) benefits:

- Reduced Project Delays: High reliability and efficiency minimize downtime caused by equipment failure or slow lifting, avoiding costly schedule overruns.

- Extended Service Life: High-quality materials (heat-treated steel gears, abrasion-resistant wire ropes) and robust design ensure a service life of 5,000+ operating hours, outperforming conventional hoists by 20–30%.

- Lower Labor Costs: Faster lifting cycles and easy operation reduce the number of workers required for material handling, cutting labor expenses by 15–25%.

3. Critical Application Scenarios

3.1 High-Rise Building Construction

- Vertical Material Transport: Electric traction hoists lift steel beams (up to 20 t), precast concrete slabs, and curtain wall units to heights exceeding 300 m, with VFD technology ensuring precise positioning at each floor.

- Suspended Scaffolding Operation: Tirak hoists support gondolas for facade cladding, glass installation, and painting, maintaining stability in high winds (up to 15 m/s) via wind load compensation systems.

3.2 Infrastructure & Heavy Construction

- Bridge Construction: Used for lifting bridge segments (up to 50 t) and tensioning stay cables, with high-precision load control (±1% of rated load) ensuring structural alignment.

- Tunnel Construction: Portable traction hoists facilitate material transport in confined tunnel spaces, with explosion-proof variants (ATEX-certified) available for underground mining or gas-rich environments.

3.3 Renovation & Restoration Projects

- Heritage Building Restoration: Manual and lightweight electric hoists enable delicate lifting of historical artifacts, stonework, and roof materials, minimizing structural impact.

- Interior Fit-Outs: Portable models lift HVAC systems, piping, and ceiling panels in completed buildings, with low noise operation (<75 dB) complying with indoor environmental standards.

4. Technical Selection Criteria

To maximize performance and safety, construction professionals should evaluate the following factors when selecting a traction hoist:

- Load Capacity & Lifting Height: Match the hoist’s rated capacity (considering dynamic load factors of 1.2–1.5) and maximum lifting height to project requirements (e.g., 100 m for mid-rise buildings, 300 m for skyscrapers).

- Power Source: Electric models for high-volume, continuous operation; manual models for low-frequency, power-free applications.

- Safety Certifications: Ensure compliance with industry standards (EN 13157, ANSI/ASME B30.16, OSHA 1926) and certifications for personnel lifting (EN 14960) if applicable.

- Environmental Adaptability: Select IP54+ rated models for outdoor use (dust/water resistance) and cold-resistant variants (-20°C to +40°C) for extreme climates.

- Operational Features: Prioritize hoists with VFD speed control, remote operation (wireless/wired), and load monitoring displays for enhanced precision.