In modern industrial operations, where operational efficiency, safety compliance, and adaptability are critical to productivity, Tirak traction hoists have emerged as indispensable lifting solutions. Engineered as specialized electric traction hoists, they leverage a rope-pulling mechanism (distinct from traditional drum-winding designs) to deliver continuous, long-distance lifting capabilities—aligning with global standards such as EN 13157 (European) and ASME B30.16 (North American) for industrial lifting equipment. This article systematically details the technical characteristics, industry-specific applications, core advantages, and safety protocols of Tirak traction hoists, providing a professional reference for industrial engineers, facility managers, and project supervisors.

1. Technical Definition & Core Technical Characteristics

A

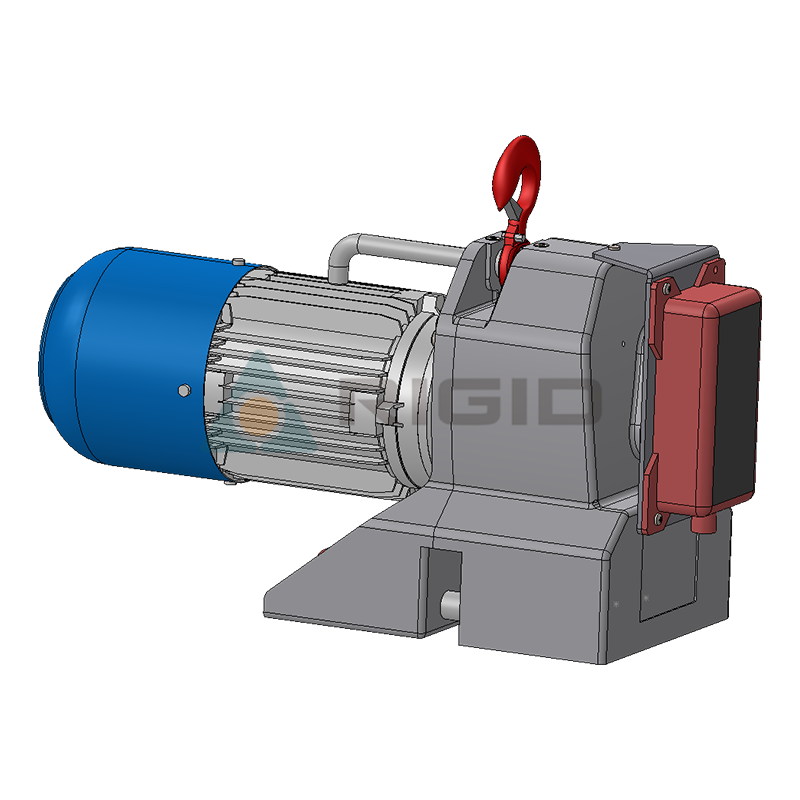

Tirak traction hoist is an electric-powered lifting device that transmits force through friction between a traction sheave and high-tensile steel wire rope, enabling vertical/horizontal load movement without rope storage limitations. Key technical specifications include:

- Load Capacity: 0.5–10 tons (standard models), with specialized variants up to 15 tons for heavy industrial use.

- Lifting Speed: 0.5–5 m/min (variable speed control), with precision positioning accuracy ±5 mm.

- Continuous Operation Range: Unlimited rope length (dependent on rope strength), supporting lifting heights up to 300 m (high-rise construction, offshore platforms).

- Structural Design: Compact footprint (typically 300×400×500 mm) and lightweight construction (20–50 kg), facilitating portable deployment.

- Safety Compliance: Equipped with fail-safe brakes (holding 150% of rated load), overload protection (110% capacity cutoff), and emergency stop systems—compliant with OSHA 1926.550 for fall protection.

1.1 Key Technical Advantages

| Technical Feature | Industrial Value |

|--------------------------------|---------------------------------------------------------------------------------------|

| Traction-Driven Mechanism | Eliminates drum capacity constraints, enabling continuous lifting over 100+ m distances. |

| Compact & Lightweight Design | Reduces transportation/installation time by 40% vs. drum hoists; suitable for confined spaces. |

| High Precision Control | Variable frequency drive (VFD) enables stepless speed adjustment, critical for delicate load positioning. |

| Robust Safety Systems | Dual braking (mechanical + electronic) and IP54-rated corrosion resistance for harsh environments. |

2. Industry-Specific Applications & Technical Requirements

2.1 Construction & Infrastructure

Tirak hoists are foundational to high-rise and large-scale construction projects, addressing vertical access and material handling needs:

- Powered Suspended Scaffolding: Integrated with gondola systems (2–10 person capacity) for facade installation, glass cladding, and maintenance. Hoists maintain stable platform tension (±2% of rated load) in wind speeds up to 15 m/s, complying with EN 1808 for suspended scaffolding safety.

- Vertical Material Transport: Lift construction materials (steel beams, precast concrete panels, tools) to heights up to 300 m, with 5–10 ton models supporting high-rise building core construction.

- Bridge & Tunnel Construction: Deployed in confined spaces (e.g., tunnel shafts) for lifting reinforcement bars and equipment, leveraging compact design to minimize workspace intrusion.

2.2 Oil & Gas (Onshore & Offshore)

In demanding oil and gas environments, Tirak hoists are engineered for explosion-proof and corrosion-resistant performance:

- Offshore Platform Maintenance: ATEX Zone 1/2-certified models (explosion-proof) lift tools, components, and personnel to offshore rigs. Corrosion-resistant (IP67-rated) materials withstand saltwater exposure and extreme temperatures (-40°C to 60°C).

- Onshore Refinery Operations: Used for catalyst replacement, heat exchanger maintenance, and pipeline inspection—handling loads up to 15 tons in hazardous (flammable gas/dust) environments.

- Well Servicing: Deployed in drilling operations to lift wellhead equipment and tools, with continuous operation capability for 24/7 work cycles.

2.3 Telecommunications & Renewable Energy

Tirak hoists support critical infrastructure maintenance in high-altitude environments:

- Communication Tower Installation: Lift antennas, transmitters, and maintenance personnel to tower heights up to 200 m. Lightweight (≤30 kg) portable models enable rapid deployment in remote locations.

- Wind Turbine Maintenance: Access nacelles (50–150 m height) to service generators and blades. Precision speed control (0.5–1 m/min) ensures safe personnel transport and component positioning.

- Solar Farm Construction: Lift solar panels and mounting structures in utility-scale solar farms, with 2–5 ton models optimizing installation efficiency.

2.4 Manufacturing & Warehousing

In industrial facilities, Tirak hoists streamline material handling and production workflows:

- Heavy Equipment Assembly: Lift machine components (gearboxes, motors, castings) during manufacturing, with precision positioning (±5 mm) ensuring component alignment.

- Warehouse Logistics: Transport bulk materials (pallets, steel coils) and finished products across large facilities, integrating with overhead rails for horizontal movement.

- Production Line Maintenance: Access elevated production equipment (conveyors, mixers) for repairs, with portable models reducing downtime by enabling quick setup.

2.5 Personnel Transport & Emergency Rescue

Tirak’s personnel-carrying variants (man riding hoists) prioritize safety for high-altitude operations:

- Industrial Inspection: Transport technicians to elevated assets (chimneys, storage tanks, power plant boilers) for non-destructive testing (NDT) and maintenance—compliant with EN 81-20 for passenger-carrying lifts.

- Emergency Rescue: Deployed in construction sites, oil rigs, and tall structures to evacuate personnel during power outages or equipment failures. Battery backup systems provide 2–3 emergency trips.

3. Core Competitive Advantages vs. Traditional Lifting Equipment

3.1 Operational Efficiency

- Continuous Lifting: Unlike drum hoists (limited by rope storage), Tirak hoists handle unlimited rope lengths, reducing downtime for rope reconfiguration in long-distance applications.

- High Productivity: Lifting speeds up to 5 m/min (empty load) and 0.5 m/min (full load) accelerate workflows—reducing material handling time by 30–40% vs. manual or drum hoists.

3.2 Versatility & Adaptability

- Multi-Environment Compatibility: Models available for general industrial, hazardous (ATEX-certified), and corrosive (marine/offshore) environments.

- Modular Integration: Compatible with suspended scaffolding, overhead rails, and custom mounting systems—supporting lifting, lowering, and horizontal traversal.

3.3 Safety & Compliance

- Redundant Safety Features: Overload protection, emergency stop, anti-fall brakes, and rope tension monitoring systems mitigate 90% of common lifting hazards.

- Regulatory Compliance: Meets global standards (EN 13157, ASME B30.16, OSHA 1926) for industrial lifting and personnel transport, ensuring audit readiness.

3.4 Cost-Effectiveness

- Low Total Ownership Cost: Durable construction (service life 10–15 years) and minimal maintenance (annual inspection only) reduce long-term expenses.

- Labor Savings: Automated lifting reduces manual labor requirements by 2–3 personnel per operation, cutting labor costs by 20–30%.

4. Safety Compliance & Operational Best Practices

4.1 Regulatory Compliance

- Adhere to industry-specific standards: EN 13157 (Europe), ASME B30.16 (North America), OSHA 1926.550 (construction), and ATEX 94/9/EC (hazardous environments).

- Personnel-carrying models must comply with EN 81-20 (passenger lifts) and undergo annual load testing (125% of rated capacity).

4.2 Routine Maintenance & Inspection

- Daily Checks: Verify rope condition (no fraying/kinking), brake functionality, and control responsiveness.

- Periodic Maintenance: Annual lubrication of moving parts, rope tension calibration, and safety system testing—documented per ISO 9001 quality standards.

- Component Replacement: Replace wire rope every 2–3 years (or per manufacturer’s guidelines) and brakes every 5 years.

4.3 Operator Training & Protocol

- Operators must complete OSHA 1910.184 (lifting equipment) training and demonstrate proficiency in load calculation, emergency procedures, and equipment limitations.

- Prohibited practices: Overloading (never exceed rated capacity), side-loading (max 5° deviation from vertical), and operating in adverse weather (wind >15 m/s, ice/snow).